Phosphorus-based Chemicals

Improve and Enhance

Main Products

Triisobutyl Phosphate

Mainly used as the ingredient of air-detraining agent in concrete admixture

Tributyl Phosphate

Mainly used as the rare earth elements extractant for many metals

Tris(2-chloroisopropyl)phosphate

Mainly used as the flame retardant in rigid and flexible polyurethane foam

Triethyl Phosphate

Mainly used as the flame retardant in many industries

Bisphenol-A Bis(Diphenyl Phosphate)

Mainly used as a flame retardant for engineering plastics.

Trioctyl Phosphate

Mainly used as the surfactant and plasticizer in pesticide and rubber

Dibutyl Phosphate

Mainly used as the rare earth elements extractant

Triphenyl Phosphate

Mainly used as a flame retardant for engineering plastics.

Trimethyl Phosphate

Mainly used as the raw material for pesticide and insecticide production

MQ Resin

Mainly used in Personal care & Cosmetic products such lipsticks, skin care etc.

Tributoxyethyl Phosphate

Mainly used as the plasticizer of surface coating such as floor care

What is phosphorus?

Defination and how it is produced

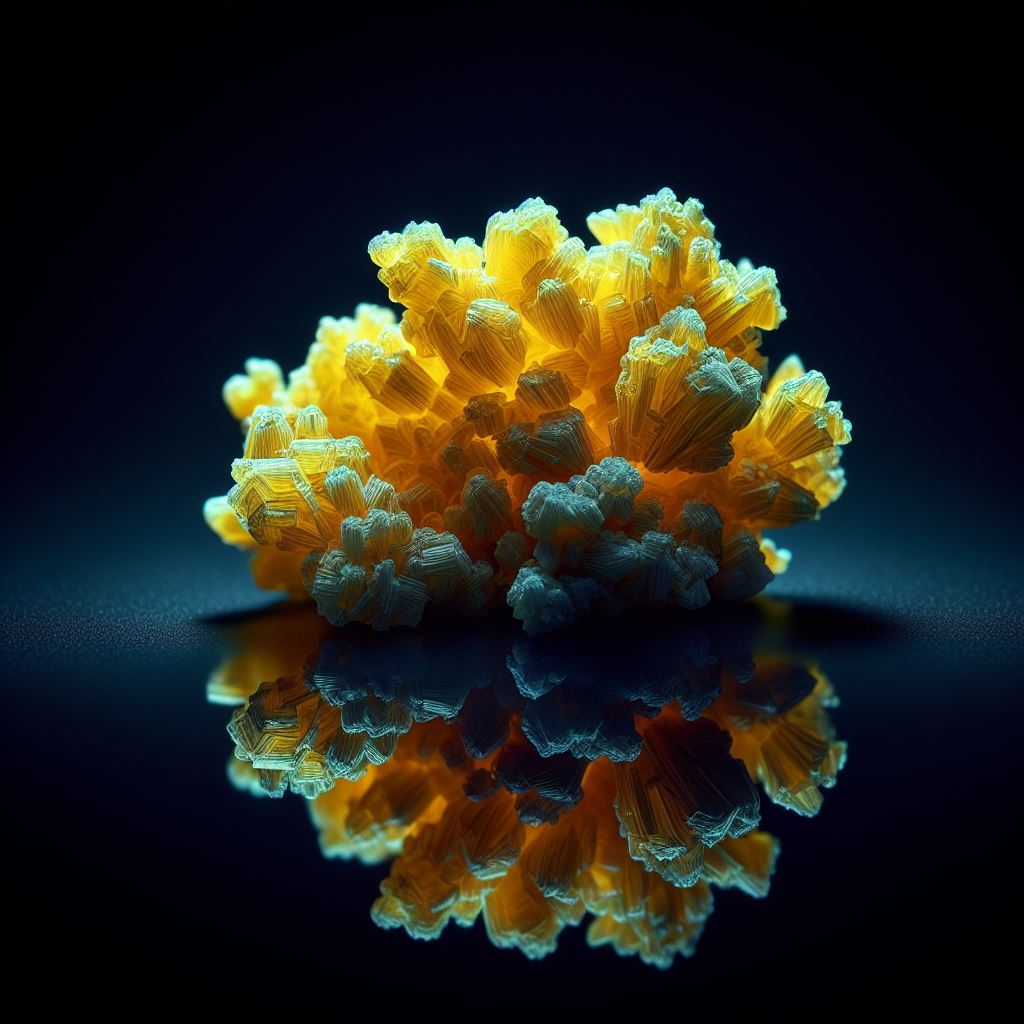

Yellow phosphorus is a white to pale yellow brittle waxy solid with a garlic-like odor. Its molecular formula is P4 with a molecular weight of 124.08. It has a relative density of 1.82 (at 20°C), a melting point of 44.1°C, and a boiling point of 280°C. The vapor has a relative density of 4.3.

Yellow phosphorus is insoluble in water but soluble in organic solvents such as fats and carbon disulfide. It can spontaneously ignite in air at room temperature and readily oxidizes to form phosphorus trioxide and phosphorus pentoxide. Therefore, it is often stored in water. When yellow phosphorus vapor encounters moist air, it can oxidize to form hypophosphorous acid and phosphoric acid. It exhibits a faint greenish fluorescence in the dark.

Currently, China has the highest total production of yellow phosphorus in the world, with over a hundred yellow phosphorus production plants. The main production facilities are located in the provinces of Yunnan, Guizhou, Sichuan, and Hunan.The yellow phosphorus production capacity of Yunnan, Guizhou, and Sichuan provinces accounts for over 80% of the national total. Due to the significant energy consumption and environmental impact associated with yellow phosphorus production, it is considered a high-energy-consuming and highly polluting industry.

The production process of yellow phosphorus is relatively simple. It involves placing phosphate ore, silica, and coke in an electric furnace in specific proportions and particle sizes. Decomposition and reduction reactions occur at temperatures exceeding 1000°C. The phosphorus vapor, along with furnace dust, is cooled and rinsed to obtain the product, while the high-temperature slag is directly discharged from the electric furnace.

Main applications and usages

Agricultural field

Phosphate ore serves as a crucial source of fertilizer. Phosphate compounds are vital nutrients for plant growth, playing a significant role in their development and overall health. By processing phosphate ore into phosphate fertilizers, essential phosphorus elements can be supplied to plants, effectively enhancing crop growth and increasing yields. Phosphate ore can be utilized through various fertilization methods, including direct application to farmland, deep placement, and seed coating.

Chemical Industry

Phosphate ore finds application in the production of chemicals such as phosphoric acid and phosphate salts. Phosphoric acid holds widespread usage as a versatile chemical, employed in diverse sectors like pesticides, synthetic detergents, dyes, and electroplating. Phosphate salts, commonly found in inorganic compounds, serve various purposes ranging from water treatment to food additives and pharmaceuticals. The extraction of phosphate salts from phosphate ore can be achieved through acid-based processes or calcination methods, followed by chemical reactions to synthesize desired compounds.

Construction Industry

The construction sector benefits from phosphate salts, particularly in cement production. By combining phosphate salts with gypsum and cement, the performance and strength of cement can be improved. Additionally, phosphate salts can effectively delay the setting time of cement, allowing for better adaptability in construction applications. Moreover, phosphate salts find utility in architectural coatings, sealants, and flame retardants.

Military field

In the military domain, phosphate ore plays a significant role due to its applications in the production of phosphate compounds. Phosphate compounds, including phosphoric acid and phosphate salts, find use as corrosion agents and incendiary materials, contributing to the manufacturing of ammunition and rocket fuels. Within phosphate ore, phosphate compounds can be utilized to produce ammonium dihydrogen phosphate, a crucial component of explosives. Ammonium dihydrogen phosphate holds importance in military and blasting sectors, facilitating the creation of explosives, rocket fuels, fireworks, and other related products. Additionally, the phosphorus content in phosphate ore can be utilized in the production of advanced military equipment such as missiles and nuclear weapons.

Partnering up with a global leading material manufacturer that supplies diversified phosphate esters chemicals.